Discover the Value of Heavy-Duty Earth Anchors in Modern Building Projects

Durable Earth supports are essential in contemporary building, supplying security against lateral pressures such as wind and seismic activity. Their robust style guarantees they can deal with considerable lots, making them suitable for numerous applications. As projects grow in intricacy, comprehending the role of these anchors becomes increasingly vital. What variables contribute to their performance, and how do they compare to conventional approaches? The response to these concerns might redefine building and construction practices.

Understanding Durable Earth Anchors

Heavy-duty Earth anchors offer as necessary elements in building and construction, offering security and assistance for numerous structures. These supports are particularly designed to be driven deep right into the ground, developing a durable connection that secures frameworks versus side forces such as wind and seismic task. Usually made from high-strength products, they are qualified of enduring substantial tons, making them optimal for applications like keeping wall surfaces, telecoms towers, and short-term structures.The installation procedure involves boring or driving the supports right into the soil, followed by tensioning the attached cables or poles. Efficient anchoring is essential for making certain that frameworks remain useful and secure with time. Heavy-duty Earth anchors additionally play a vital duty in enhancing the life-span of construction jobs by protecting against soil disintegration and shifting. Understanding the application and abilities of these anchors is important for engineers and project managers aiming to achieve structural integrity in different atmospheres.

The Design Behind Earth Anchors

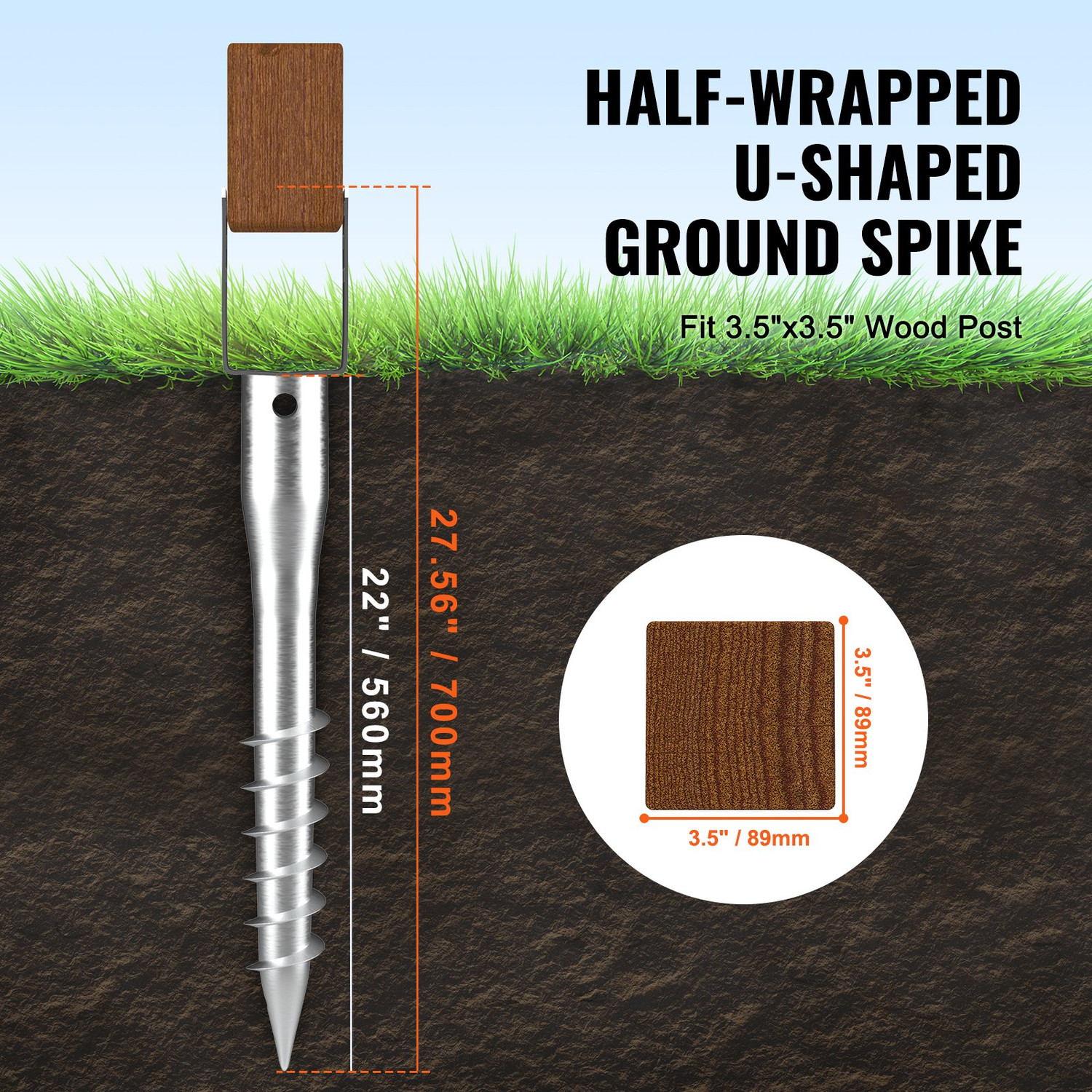

The performance of heavy-duty Earth anchors is mostly credited to the engineering principles that underpin their design and capability. These anchors are carefully developed to hold up against significant tensile and shear forces, guaranteeing security in different soil problems. Their structure usually consists of a shaft, helix, or plate that secures the support deep into the ground, making best use of resistance versus pullout forces.The products utilized in producing these anchors are picked for their toughness and toughness, commonly comprising top-quality steel to protect against corrosion and structural failing - tensile load anchors. The installment procedure is similarly crucial; specific positioning and deepness are determined based upon dirt structure and lots requirements.Furthermore, advanced engineering techniques, such as limited aspect analysis, are employed to maximize support styles for particular applications. This mindful factor to consider of environmental aspects and mechanical principles ensures the dependability and performance of sturdy Earth supports in modern-day building tasks

Advantages of Utilizing Durable Earth Anchors

Sturdy Earth anchors provide substantial advantages in building by improving stability and support for various frameworks. Their trustworthy performance adds to much safer building practices while also providing cost-effective remedies for taking care of dirt problems. As a result, these anchors are progressively acknowledged for their worth in modern engineering jobs.

Enhanced Stability and Support

While construction projects often encounter obstacles pertaining to security, using Earth anchors supplies a trustworthy solution to boost architectural assistance. These sturdy anchors are made to penetrate deep right into the ground, making certain a safe and secure hold that endures numerous environmental variables. By increasing and rearranging tons resistance to side pressures, Earth anchors significantly minimize the threat of structural failure. Their capacity to stabilize maintaining walls, foundations, and short-term frameworks enables more secure building and construction practices. Furthermore, they can be utilized in diverse soil conditions, making them functional for different tasks. The combination of Earth anchors not only strengthens frameworks however additionally advertises longevity, ensuring that building jobs continue to be resistant with time.

Affordable Soil Solutions

By utilizing durable Earth supports, building and construction tasks can attain substantial cost financial savings without endangering quality or security. These anchors offer trustworthy stablizing, decreasing the need for extensive excavation or using added materials, which can blow up task budget plans. They are made for toughness, lessening maintenance costs and boosting the total lifespan of frameworks. Furthermore, their installment is typically quicker and less labor-intensive compared to conventional techniques, enabling faster project completion and minimized labor costs. This performance translates into reduced total building and construction expenses, making heavy-duty Earth anchors an attractive choice for specialists seeking to optimize their spending plans. Eventually, the calculated use of these supports cultivates both architectural and economic advantages in modern-day building practices.

Applications in Different Building Tasks

Earth Anchors vs. Typical Anchoring Methods

The contrast in between Earth anchors and standard anchoring approaches highlights numerous essential variables in building and construction. Boosted load-bearing ability and setup effectiveness are vital benefits of Earth anchors, particularly in difficult settings. Furthermore, their durability under different problems positions them as a remarkable selection for lots of applications.

Improved Load-Bearing Capacity

While typical anchoring methods have actually long been made use of in construction, durable Earth supports offer a significant improvement in load-bearing capacity. These ingenious supports are developed to endure higher pressures, making them ideal for numerous demanding applications, consisting of industrial structures, bridges, and keeping walls. Unlike standard supports, which might depend on rubbing or superficial embedment, durable Earth supports utilize deep securing strategies that engage the soil a lot more efficiently. look at more info This deeper combination allows them to withstand higher tensile and side loads, providing raised security and sturdiness. Because of this, projects making use of durable Earth anchors can attain exceptional structural stability, minimizing the risk of failure under extreme conditions and guaranteeing durability in efficiency contrasted to typical anchoring solutions.

Setup Performance Comparison

Contrasting installation effectiveness exposes that sturdy Earth supports substantially streamline the anchoring process in building and construction jobs. Unlike typical techniques, which often need comprehensive excavation and manual work, Earth supports can be installed quickly with very little site disruption. Their style allows for driving directly right into the ground, lowering time invested in setup.Furthermore, Earth anchors are generally lighter, making them easier to move and manage on-site, which can significantly decrease labor expenses. On the other hand, standard anchors might require much heavier equipment and more complicated setup methods.

Resilience in Numerous Conditions

Sturdiness in various environmental conditions plays a vital role in establishing the effectiveness of securing systems. Durable Earth anchors show remarkable strength compared to conventional securing approaches, such as concrete or steel risks. These anchors are developed to withstand extreme weather condition, dirt erosion, and temperature changes, making them suitable for varied building and construction tasks. Their corrosion-resistant materials ensure long life, reducing upkeep expenses in time. In contrast, standard techniques often fail under severe problems, causing structural failings and boosted replacement expenses. Additionally, Earth supports can adapt much better to various soil kinds, offering reputable grip and stability, while conventional methods may have a hard time in loose or changing soils. Subsequently, heavy-duty Earth supports supply an even more durable solution for modern construction demands.

Installment Process and Ideal Practices

The setup of heavy-duty Earth anchors calls for cautious planning and precision to ensure peak performance and security. Initially, site assessment is important to establish soil problems and anchor positioning. Professionals should conduct dirt examinations to identify the suitable anchor type based on load-bearing capacity. Once the website is reviewed, appropriate placement and depth are crucial throughout setup. Utilizing specialized equipment, supports must be driven or pierced right into the ground to the defined deepness, making certain they are safely positioned.Following installation, tensioning the supports is necessary for attaining ideal performance. This process involves using force to the support to ensure it is qualified and firmly embedded of holding up against anticipated lots. Regular examinations and upkeep are also advised to keep an eye on anchor efficiency in time. Sticking to these ideal techniques will improve the efficiency of sturdy Earth supports, adding to the general success of building projects.

Future Patterns in Earth Anchor Technology

Improvements in Earth support innovation are poised to substantially boost their application in click for more construction projects. Technologies such as wise sensors incorporated into supports will enable real-time surveillance of soil problems and anchor performance. This data-driven approach allows for positive adjustments, ensuring structural honesty and safety. Furthermore, the advancement of green materials is getting traction, reducing environmental effect while maintaining durability.Furthermore, modular support systems are emerging, facilitating quicker setups and adaptability to various soil types and job demands. Automation in the setup process is likewise prepared for, which might reduce labor costs and enhance accuracy. The combination of expert system in design and evaluation will certainly maximize support placement and boost load-bearing capabilities. On the whole, these future patterns are anticipated to reinvent the reliability and efficiency of durable Earth supports, making them indispensable in modern-day construction practices.

Frequently Asked Inquiries

How Do Climate Problems Affect Heavy-Duty Earth Anchors?

Weather significantly affect sturdy Earth anchors, affecting their installation and efficiency - tensile load anchors. Variables such as soil dampness, temperature fluctuations, and rainfall can affect dirt stability, causing possible support failing or lowered holding ability in various atmospheres

What Materials Are Commonly Made Use Of in Heavy-Duty Earth Anchors?

Durable Earth supports are generally constructed from materials such as why not try this out galvanized steel, stainless-steel, or high-strength alloys. These materials supply toughness and resistance to rust, making sure the supports perform effectively in requiring ecological problems.

Can Earth Anchors Be Reused in Different Projects?

Earth supports can often be reused in different jobs, provided they continue to be structurally sound and meet job specs. Appropriate examination and maintenance are important to guarantee their efficiency throughout succeeding installations in different building and construction applications.

What Is the Lifespan of a Heavy-Duty Earth Support?

The life-span of a durable Earth support normally varies from 20 to half a century, depending upon variables such as worldly high quality, installation approaches, and environmental conditions. Normal examinations can help assure peak efficiency throughout its life expectancy.

Exist Any Environmental Concerns With Utilizing Earth Anchors?

Problems bordering Earth supports mainly associate with soil disturbance, possible effect on regional environments, and groundwater flow modifications. Appropriate installment and adherence to environmental regulations can minimize these issues, making sure minimal eco-friendly disruption during building tasks. Unlike conventional supports, which might rely on friction or shallow embedment, durable Earth supports use deep securing methods that involve the dirt more effectively. Contrasting setup effectiveness reveals that durable Earth supports greatly improve the securing process in building and construction jobs. Sturdy Earth supports show superior durability contrasted to typical anchoring methods, such as concrete or steel stakes. Utilizing specialized equipment, supports must be driven or drilled right into the ground to the defined depth, making certain they are securely positioned.Following setup, tensioning the supports is necessary for achieving perfect performance. Technologies such as smart sensors integrated right into supports will allow real-time monitoring of dirt problems and anchor efficiency.

Comments on “Don’t Install Without This tensile load anchors Inspection List”